Processing

Organic production process to obtain purest quality products

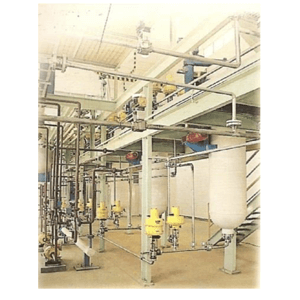

Oil Distillation

As a first step, wood is segregated into various grades depending on resin density, and each grade is separately used for extraction. The wood is chopped and dehumidified with electrical dryers, or in semi-shaded sunlight, for 3 to 4 days, and 3 to 4 hours per day. Later, the chopped bits are crushed into about 1 mm grains to increase the surface area of extraction. Based on odour requirements, the material is soaked in a pot for 200 to 400 hours for fermentation. Depending on the distilling capacity and the quality of wood, the material is loaded into extraction vessels to get the best recovery.

Agar Boya or Agar wax is extracted from the non-infected white wood. We have set up 500 to 1,000 kg capacity units at some of our primary processing factories. After chopping the trunk and grading the wood, leftover white sap wood is cut into smaller pieces of 2 to 3 cm length, and about 0.5 thickness. The material is then soaked in the fermentation vessel for 2 to 3 weeks, and extracted through the hydro distillation vessel which works on firewood.